Gas Hobs

Post from EditorialsThe new gas hobs that provide energy savings, cooking consistent and satisfactory way, without neglecting aesthetics and design together with ease of use.

General considerations on gas hobs

When it comes to saving energy, embracing all areas of home life and work in which the 'energy plays an important sector in the ordinary course of its activities. Materials, methods of production, processing cycles, if well chosen and designed, can cause great advantages both from the economic point of view and from the point of view of environmental.

Materials, methods of production, processing cycles, if well chosen and designed, can cause great advantages both from the economic point of view and from the point of view of environmental.

Every sector of production, regardless of its size and importance, can and should take all the necessary measures to reduce costs and the use of precious energy sources.

One such source is the gas, which is defined as a non-condensable gaseous at room temperature, it in particular for domestic use is presented mainly in the form of LPG and methane.

The LPG also known as liquefied petroleum gas, is nothing but a mixture of hydrocarbons wherein the propane is the main component.

Methane is a hydrocarbon very simple, which has the characteristic of burning in the presence of oxygen, thereby producing carbon dioxide, water and heat, a feature which makes it extremely convenient for energetizzare boilers, stoves and other elements of home use.

So that the combustion takes place of the gas used, it is necessary to employ the burner fundamental component of a combustion plant, which is necessary to facilitate the mixing of a fuel and an oxidizer, with consequent production of flame.

Using the principle defined above, the manufacturers of cooktops for domestic and industrial use, are marketed hobs of different aspects and features, whose gas supply, is the common feature. Generally, those who need to buy a stove with gas supply, taking into account some basic elements, such as aesthetics and design, materials, size, type and characteristics of the burners, ease of cleaning and maintenance, cost performance, service efficient safety devices used.

Generally, those who need to buy a stove with gas supply, taking into account some basic elements, such as aesthetics and design, materials, size, type and characteristics of the burners, ease of cleaning and maintenance, cost performance, service efficient safety devices used.

All factors considered, are certainly useful and required in order to correct and careful choice of the hob, but unfortunately neglects the consideration relating to the consumption of gas between the various levels at the same cooking time.

Neglecting this parameter, for those who regularly employs a hob in which there are burners normal and those more substantial for fast cooking, wastes the equivalent to 20 to 25% of gas in multiple.

What to consider buying a stove

To economize on gas, it must be ascertained basically that the combustion occurs in a correct and that the concentrate burner the flame evenly over the entire surface of the pot. To verify that the gas is mixed properly it is necessary that the flame does not produce black smoke that in addition to blacken pots and accessories, warns that the 'air circulating in the plant is not sufficient to ensure a proper combustion.

To verify that the gas is mixed properly it is necessary that the flame does not produce black smoke that in addition to blacken pots and accessories, warns that the 'air circulating in the plant is not sufficient to ensure a proper combustion.

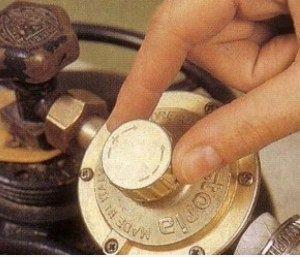

Should this occur, it is necessary to act on the regulator positioned on the tube of the gas supply, the controller can increase or reduce the intake of air into the circulation, by opening or closing through a device the inflow of air.

During the operation of air control, make sure that the flame coming out of the burner, to take a picture tight and bluish in color, without moving away from the holes on the burner over to the point that tend to go out.

To obtain therefore, the reduction of the gas used for the same cooking time is necessary to replace the normal radial burners with burners of new type, capable of providing a flame delivered in a more homogeneous.

The new technology of modern gas hobs

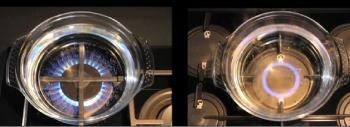

Companies such as Smeg , Ariston , Foster , etc.., produce hobs with different characteristics but in particular the plans of Ariston called Direct Flame Series New Light Collection Hotpoint, guarantee savings sensitive gas consumption compared to conventional burners. The technology Direct Flame precisely, is based on new burners revolutionary design, they consist of a single piece and flat and have the characteristic of being covered with hundreds of small holes neatly distributed, through which the flame propagates upward in a perfectly homogeneous.

The technology Direct Flame precisely, is based on new burners revolutionary design, they consist of a single piece and flat and have the characteristic of being covered with hundreds of small holes neatly distributed, through which the flame propagates upward in a perfectly homogeneous.

The manufacturer guarantees that: unlike traditional flame burners radial, which concentrate the heat only on some parts, the micro holes of the burners radiate vertically Direct Flame the flame for a better distribution of the heat on the bottom of the pan, which receives the heat evenly over the entire surface.

Cooking with plans Direct Flame Light is faster and use of energy (at the same time) is less due to better heat distribution. The low fuel consumption guaranteed by Direct Flame burners, they save 20% of energy and time compared to conventional burners.

The low fuel consumption guaranteed by Direct Flame burners, they save 20% of energy and time compared to conventional burners.

Plans for this LIGHT is marked by the symbol EcoTech that is a guarantee of environmental and energy performance.

The guarantees offered by the manufacturer, of course certified by laboratory tests and checks severe, are certainly not at the expense of aesthetics and minimalist design of the product, in fact the kitchens of the line LIGHT are the right combination of form and function, certainly much appreciated by those who must use them every day in a practical and secure.

The materials used for their construction, stainless steel and toughened glass, ensure solidity and safety together with an ease of cleaning and maintenance.

In particular, the direct Flame burners are extremely easy to clean because of being blocks, are placed with no gaps and can be easily flipped to be washed by hand or in the dishwasher.

L 'use of a cooking system like the one described, be assessed in particular when cooking delicate foods such as creams, etc. passed., Where the' uniformity of cooking as well as reduce the time, gives the food a taste smoother.

79733 REGISTERED USERS