Wood fiber for a natural insulation

Post from EditorialsThere are many materials to insulate the house but few are as efficient as wood fiber. The panels of wood fiber are the natural alternative for isolating house.

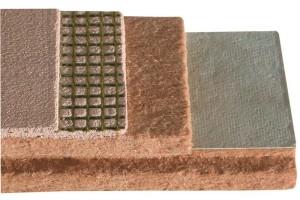

The characteristics of wood fiber

The wood fiber is one of the main materials used in green building to isolate the house in a natural way. Obtained thanks to the processing of waste wood, and already recycled source, it differs from the total insulation of petrochemical origin mainly being fully compostable once its life ends. Nothing special waste dumps and then with wood fiber, as long as it is not treated with special glues or additives.

Slightly more economic of cork, even if more expensive compared to polystyrene, the wood fiber for a natural isolation differs from the latter for its ability to let through water vapor, ie for the breathability of the material itself.

Normally you reach the higher level of insulation with a considerable attenuation of thermal bridges, when applying the insulating material on the cold side of the walls of a building, hence the name of the outer coat.

However sometimes it is not possible or is simply uneconomic to apply the insulation panels outside the building, so you have to go inside to insulate the house.

At home, as is known, we produce a considerable amount of water vapor, especially during the night hours because of breathing. It is therefore important that the insulation panels applied to the walls act as moisture regulator, absorbing the excess moisture present in the air and dropping it at a later time.

The manufacturing companies in Europe

The producers reside mostly in Northern Europe (Switzerland, Germany, Poland), where you have more raw material; industry leaders are the Swiss PAVATEX the Polish STEICO or German GUTEX, BEST WOOD SCHNEIDER, HOMATHERM.

The producers reside mostly in Northern Europe (Switzerland, Germany, Poland), where you have more raw material; industry leaders are the Swiss PAVATEX the Polish STEICO or German GUTEX, BEST WOOD SCHNEIDER, HOMATHERM.

In Italy instead the products come mostly from distribution companies with registered office in Bolzano, Trentino-Alto Adige, such as NATURALIA BAU, NORDTEX, LEO BODNER, 3THERM, each developing their own systems for a more complete isolation and performance.

Why should we put down a coat of wood fiber

The coat with panels in wood fiber has numerous advantages compared to other synthetic solutions, for example, the phase shift when subjected to the heat of the sunlight, or the dimensional stability of its elements.

The phase shift indicates the ability of a material to let through by the heat. The wood fiber has a high phase shift value, it follows that in the summer a coat wood fiber ensures a cooler environment inside than a coat polystyrene or mineral wool, because the peak of maximum heat inside the building will occur only during the night, which means when the outside temperatures will be more acceptable.

A little experiment to evaluate different materials

Not all materials behave in the same way when subjected to a heat source. Just do a little experiment letting in the sun a polystyrene panel and a panel of wood fiber. The polystyrene will warm up quickly and once in the shade will cool more quickly.

The wood fiber will employ on the contrary more time to heat up and once ceased the exposure to the sun will release the accumulated heat more slowly.

Ultimately if you must make a coat for improving the thermal insulation might as well make sure that the material you put in the work to be useful both in winter and in summer!

How to lay a natural insulation in wood fiber

The wood fiber is a relatively light material, easy to carry and to cut.

The method for laying a coat of wood fiber is the same one that you use with cork panels, calcium silicate or petrochemical origin. Just apply a layer of glue with a notched trowel taking care that the material covers the entire surface and fix the panel to the wall. If in the presence of a perforated wall, a precaution may be to avoid using a hammer drill so that the surface is not damaged and can pull the plug correctly.

Another recommendation is to stagger the panels to avoid thermal bridges and take care to cut the panels around the windows as indicated by the installation manual. The openings are in fact considered to be critical in laying a coat.

Subsequent to installation of the panels must cover the entire surface with the specific retina plaster glass fiber or jute and smooth the whole up to obtain the ideal support for finishing.

The cost of wood fiber

The wood fiber is one of the best solutions for natural insulation, although at the moment it is necessary to produce a high energy expenditure, as they point to the supporters of the petrochemical, would arise the higher costs compared to synthetic materials.

While taking into consideration that the incidence increased to achieve a coat insulation remains that of labor and not only of the material, a polystyrene panel costs little more than half compared to a panel of the same thickness but made of wood fiber.

All that remains, therefore, that invest in this relatively new technology and contribute, so that the production methods improve both necessary and less and less energy for the production of the panels.

79870 REGISTERED USERS