Lightweight concrete for foundations

Post from EditorialsWith the new lightened concrete substrate can be achieved in a short thick numerous benefits including a good acoustic and thermal insulation.

The new role of the substrate

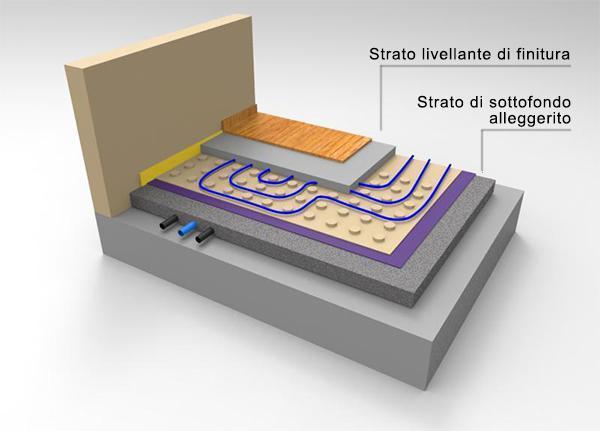

Thanks to the evolution of the technique in the production of lightweight concrete, at the request of transmittance values more and more restricted imposed by the various parts of the building, the substrate, ie the stratigraphy between the insole and the flooring, has acquired little by little a role of increasing importance in the delicate design of a building and its energy requalification.

The substrate now is not limited to being a mere supporting layer of the floor but it is a real piece of project to which to which we need to devote due attention.

In the image an energy improvement by the study Lacasapensata with interposition of a lighter substrate. The stratigraphy is clearly visible from the cut made in the slab for the placement of an internal staircase.

The function of the lightweight concrete for substrates

The functions of the lightweight concrete for substrates are manifold: it is used as a filler layer, for example in the structural reinforcement of a floor in which it is important not to further burdening on the structure, covers and protects the installations that run in the floor, thermally insulates the floor, isolate acoustically overlapped housing units.

Especially in floor radiant plants, ie in the absence of radiators for heating but in the presence of coils embedded in the floor, a lightened substrate made above the slab helps to prevent that the heat emanating from the plant falls down and disperse.

Monolayer or bilayer, the lightweight concrete substrates are classified mainly by the number of functional layers and their thickness.

In the past, in the absence of current restrictive regulations in terms of insulation parameters limit, the layer was only one, and the only function required was the support of the floor.

Today substrates consist of two layers are the norm in the design of new buildings or in upgrading the energy efficiency of the existing.

The bottom layer rests on the insole and is made of lightweight concrete, the upper one is defined finishing layer and must ensure the perfect flatness, uniformity and rate of moisture for laying of the flooring in a workmanlike manner.

What comprises the lightweight concrete.

There are several types of lightweight concrete; generally that employed for the realization of the substrates is composed of cement or lime as binder and inert material, ie sands and gravels mixed in different proportions, depending on the necessity with granular or crushed insulating material.

In the photo the solution with cork CorkPan by Tecnosugheri.

For insulation can be adopted different solutions, such as expanded clay, perlite, vermiculite, cork blond or better toasted, expanded polystyrene.

Alternatively, it can be used the so called cellular concrete, obtained by mixing to the concrete mix a specific foam that increasing in volume creates a cell structure closed air-coated cement and no communication between them. Obviously the degree of insulation depends on the choice of the insulation: expanded clay is best if you want a substrate with higher density, understood as weight in kilograms per cubic meter of material, whereas if you bet on the lightness and isolation are more indicated the cork or its synthetic variant polystyrene.

Obviously the degree of insulation depends on the choice of the insulation: expanded clay is best if you want a substrate with higher density, understood as weight in kilograms per cubic meter of material, whereas if you bet on the lightness and isolation are more indicated the cork or its synthetic variant polystyrene.

Comparing the weight of a traditional concrete and a lightweight concrete, the different values depend on the type and amount of insulation per cubic meter, however, basically the density values go from 2000-2400 Kg/ mc of a traditional substrate to the only 400-500 kg/ mc of a lightened one.

The regulations regarding the lightweight substrates.

The regulations regarding the lightweight substrates are different. The main one is certainly the Decree 311-06 on thermal insulation and energy efficiency in buildings, which determines in various tables the limit values of transmittance in relation to the various constituent parts of the building shell.

Over the years and in the final revision with the new decrees of the Law 90/2013, in force since last Oct. 1, these parameters were shrinking, gradually demanding more and more insulating materials.

Comparison of U Thermal transmittance values relative to horizontal opaque surfaces of the floor, to the outside, no air-conditioned environments or basements in buildings undergoing redevelopment Energy (thermal zone E).

| 2006 | Year 2015 | Year 2021 | DELTA |

| 0.43 W / m2K | 0.31 W / m2K | 0.29 W / m2K | 33% |

In the Lombardia region, for example, which is the E climate zone, relative to the limit values of the thermal transmittance of opaque structures of the floor of an unheated room, changing from a value of 0.43 W/ m2K in 2006 to 0.31 W/ m2K of 2015, in anticipation of getting to 0.29 W/ m2K by 2021.

As for acustis, however, the relevant legislation is the Framework Law no. 447 of 26/10/95 and in particular the implementation decree DPCM 5/12/97 on the passive acoustic requirements of buildings, which for the first time introduced the need to design the package substrate by regulating several factors, including the foot traffic noise, external ones, the noises of the plants and between different units.

The Ethic project of recycling corks

For several years various NGO, including Libera, participate in an ethical project of collection and recycling of cork for the subsequent grinding and production of lightweight concrete.

The numbers are impressive: it is estimated that since the beginning of the campaign, actually called Etico, promoted by Amorim Cork Italia has been collected over 170 million corks, corresponding to 100 tons of recycled material and that consequently the objective is to produce from scratch consuming energy and raw materials.

Good point, so when choosing which material to use for the lightened substrate at home.

79806 REGISTERED USERS