Glass fiber mesh

Post from EditorialsThe use of modern networks in fiber glass for the consolidation of vertical and horizontal structures in replacement of traditional metal nets.

The need to strengthen buildings

Following the earthquake of November 1980, the housing stock of the Southern area in Italy has undergone large-scale collapses and damage that would result in the relocation to a new site, geologically safer, of whole towns rebuilt with antiseismic criteria.  The remaining part of the housing stock, consisting mostly of masonry buildings and old buildings made of chaotic and heterogeneous masonry, required the interventions of stabilization and strengthening in order to achieve a level of security sufficient to withstand any later seismic event.

The remaining part of the housing stock, consisting mostly of masonry buildings and old buildings made of chaotic and heterogeneous masonry, required the interventions of stabilization and strengthening in order to achieve a level of security sufficient to withstand any later seismic event.

All performed interventions, even with very different methods among them, tended to the achievement of the structural efficiency of the construction in order to be able to ensure the structural safety.

To achieve such a result in particular for masonry buildings is necessary to know the quality of the masonry and its static scheme in relation to stress that interest it, in order to better organize the distribution of stresses it has to withstand stress, when this condition is not met, it is necessary to proceed with actions aimed at increasing the strength of the structure as a whole.

Basically to operate an increase in the overall resistance of the structure is necessary to act by improving the quality of the masonry or redistributing in a more rational way the load-bearing elements in order to reduce the severity of the loads.

It is evident as the set two interventions reach the best condition to ensure optimum resistance to the whole building. Not being able to always proceed with a redistribution of the structural parts in a different way from the existing one, it is possible in a simpler improve the quality of walls through localized strengthening systems.

Differentiated intervention system

One of the most used system is the consolidation through the use of welded steel mesh, consisting of iron rods arranged in a square mesh with variable pitch, united to each intersection together by welding for electrical resistance. The application of such nets on the walls, floors, vaults, etc., If on one side has allowed to increase the strength characteristics of the consolidated structure, on the other hand has led to the passing of time the occurrence of a series of criticalities such to cause damage to other finishing works arranged on the treated structures.

The application of such nets on the walls, floors, vaults, etc., If on one side has allowed to increase the strength characteristics of the consolidated structure, on the other hand has led to the passing of time the occurrence of a series of criticalities such to cause damage to other finishing works arranged on the treated structures.

The causes of such phenomena are attributable to several factors: defects of laying, concrete coverings insufficient, not adequate anchorages, oxidation with consequent expulsion of the layers of surface finish, size of the structural mesh not adequate, etc ..

In addition to the criticality described above, together with other drawbacks such as the difficulty in operational movements in the pipeline, the poor adaptability to cover surfaces with shapes and even complex geometries, excessive weight in relation to other materials much more performing, the need for maintenance more assiduous, they have caused the decrease of the use in favor of the most modern nets in fiberglass.

The use of the fiberglass nets

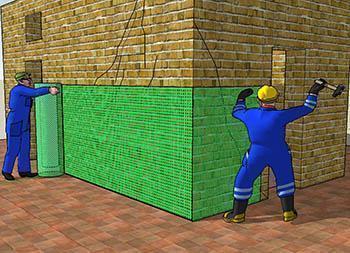

The modern nets in continuous fibers of glass, extremely resistant thanks to the grip with thermosetting resins, are constituted by panels made by crossing between them a square mesh of interwoven elements, capable of making the net extremely robust and easily adaptable to any surface. With nets in fiberglass you can perform any kind of strengthening of horizontal and vertical structures, faster, more easily and sent over the use of traditional wire mesh.

With nets in fiberglass you can perform any kind of strengthening of horizontal and vertical structures, faster, more easily and sent over the use of traditional wire mesh.

By virtue of durable material they are made of, the glass fiber nets are especially suited for recovery interventions and strengthening of architectural works of great value, thanks to their biological compatibility with classic materials.

The impossibility of showing oxidative phenomena, with consequent damage of the overlying materials, enables to minimize the thickness of the opaque surfaces resulting in manufacture and economic resources economy. This last peculiarity is a big advantage for all consolidation work carried out in particularly aggressive environments, such as those in the vicinity of marine areas. The low weight per square meter of the net promotes the on-site handling. By way of example it should be considered that a welded mesh panel consists of 5 mm diameter rods arranged in a square mesh with a pitch of 100x100 mm weighs about 3 kg/ sqm, while a square meter of the network of glass fiber with a step thickest (60x60 mm), weighs about 500 grams.

This last peculiarity is a big advantage for all consolidation work carried out in particularly aggressive environments, such as those in the vicinity of marine areas. The low weight per square meter of the net promotes the on-site handling. By way of example it should be considered that a welded mesh panel consists of 5 mm diameter rods arranged in a square mesh with a pitch of 100x100 mm weighs about 3 kg/ sqm, while a square meter of the network of glass fiber with a step thickest (60x60 mm), weighs about 500 grams.

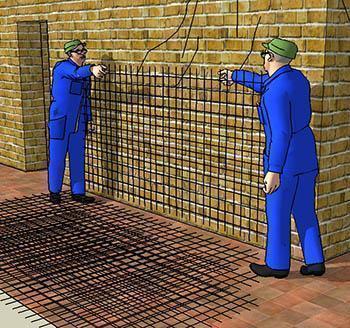

Besides the advantages described above, the use of glass fiber nets requires neither special equipment nor specialized workers, in fact the network, generally supplied in rolls of length up to 40 meters and height of 2.00 meters, can be cut without problems and shaped according to the type of application required.

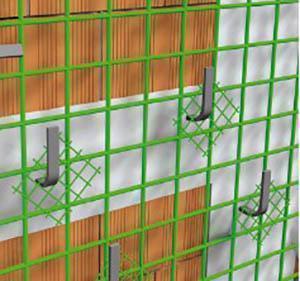

The length of the roll also offers the possibility of reducing the number of overlaps, with respect to the use of metallic nets; this makes it easier and safer the strengthen also of very slender structural parts, on which the thicknesses of the rods force to increase the protection layers above. As a complement to the use of networks in glass fibers, are provided to the useful elements as the reinforcing corner constituted by the network in the composite material created to consolidate continuity with angled walls, columns, pilasters, cornices, etc..

As a complement to the use of networks in glass fibers, are provided to the useful elements as the reinforcing corner constituted by the network in the composite material created to consolidate continuity with angled walls, columns, pilasters, cornices, etc..

The links of the networks to the masonry, takes place by means of connection systems consisting of forks of variable length, which are matched to handkerchiefs network, specially designed for an increase collaboration of the connection point with the entire structure.

Thanks to the flexibility in all directions, networks of glass fiber are particularly useful in the reinforcement of structural elements of architectural value, which for the context in which they are inserted, can not undergo alterations in shape and geometry.

Columns, friezes, half-columns, pilaster strips and other can not easily be reinforced with metal mesh also the particular constitution of some mortars used in old buildings is more sensitive to the presence of oxidising elements with consequent alteration of the surfaces in contact.

The packaging in rolls of the network allows its storage in less space with the same square meters, compared with panels made of wire mesh, which is very useful in those situations where operational free spaces available are scarce.

79734 REGISTERED USERS