Faux stone panels

Post from EditorialsThe fake stone panels, precast, are for the home and give warmth, beauty and decorative relief decided by the visual impact!

Faux stone walls

In today's restructuring, the flavor of the old is always sought after, despite the decor has a contemporary look, the design is linear and simple, with smooth surfaces, easy to clean, with clear tones.

The willingness of users homeowners is often to create functional spaces of contemporary style and seating areas featured more traditional, with the inclusion of its elements of nature, such as stone and wood.

It is in these environments that fit the panels imitation stone: prefabricated slabs capable of simulating the appearance of the stone is in the shape it is in the shade.

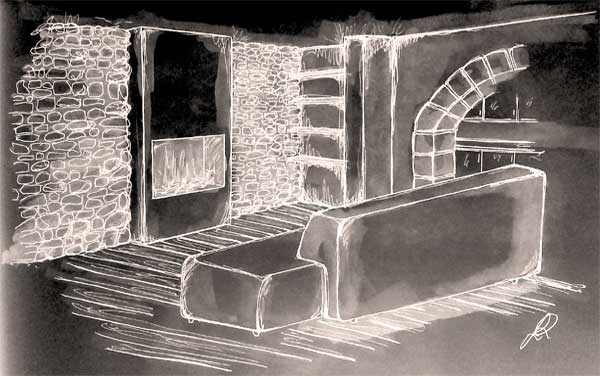

Pleasant is to imagine, for example, a living room characterized by the presence of a fireplace, a stone cladding with comfortable seating in front of the current design, perhaps to light shade, to counteract the choice of a darker stone.

On the back, an arc from the traditional flavor that introduces the kitchen and shot highlighting its modern lines, smooth surfaces, the neutral tones lacquered finish, then brilliant.

The idea has been sketched and made visible in the image below using a perspective that frame the entire environment, made of various styles well integrated.

Today you can make concrete what you want, through cost-effective solutions, easy and with a minimally invasive surgery.

Panel Features

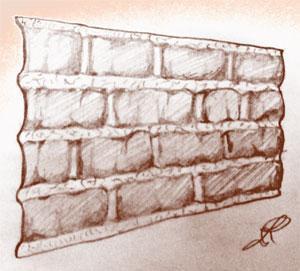

The panels in synthetic stone slabs are pre-built, made in composite materials and therefore to be crosslinked polyester resin in glass fiber, with the addition of mixture obtained by powder of natural stones.

The size varies according to the company that produces them; However, it is on average about 1.5 m high and 1.20 m wide or 2.85 m to 1.30 m high with a total area of 3.70 square meters per plate.

Also the thickness is variable but we can assert about 1cm, then a few millimeters to a coating that faithfully reproduces the volume of dense natural stone substances: stones and also bricks.

In addition to panels, on the market, there are specific sections for the pillars of the side 30 or 40 cm and elements forming bows for amplitudes not exceeding three meters.

The positive aspects of the product which tend to choose it are multiple and summarized as follows:

- Mechanical resistance and chemical

- Shock resistance

- UV resistance

- Resistance to potassium nitrate, commonly called saltpeter

- Frost Resistance

In addition, it is easy to assemble, easy to remove and repair, light texture, durable, applicable on any surface for both indoor and outdoor, ecological, waterproof, unalterable, adaptable to various environments, with low shrinkage and minimal expansion, in real stone aesthetic.

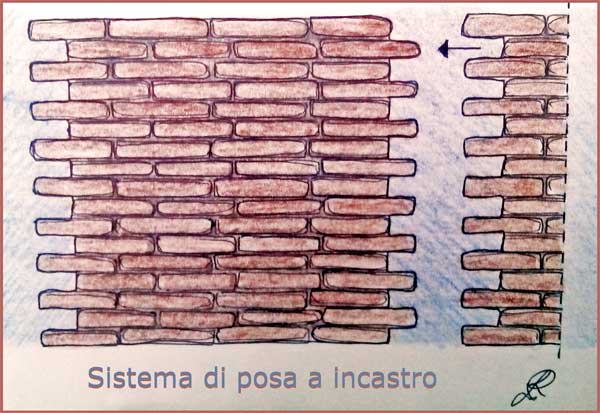

Regarding the texture you have a wide choice in both the type and colors, generated by natural dyes; Furthermore, the system of laying is in interlocking, or is made by assemblying modular elements.

Assembly steps

The installation is very simple and can be made in DIY mode; however, it is preferable to let the help of a decorator, expert in the field, especially for masking well the joints between one panel and the other.

The first step is to reduce preformed panels in sizes appropriate and therefore we will use a pencil and a straight edge or length of hardwood to mark the lines of the cut. The incision will be accomplished with the aid of a circular saw, a grinder or a simple hacksaw.

We are also advised to wear gloves and eye protection, to avoid any unpleasant incident!

Subsequently we spread the glue on the surface to be coated, using a toothed trowel so as to make better adhesion of the sheets to the wall and in more, muffle the sound of vacuum in the event that you go to strike an object.

It follows the actual pose of the elements in faux stone by means of screws and plugs, joining to one another and interlocking them so as to generate joints thickness narrow or wide depending on the circumstances and the types of panels.

The holes in the wall plugs and leaks generated must be masked with stucco, a thick cream without lumps mixed with water and applied with a spatula or with a pastry bag.

Finally, following the finer details and application of a dye solution oxide distributed, there where necessary, with a simple wet brush.

Considerations

The panels are an alternative solution with respect to the walls real stone since they can be employed for various uses, installed in different environments without the requirement to erect massive walls species there where it needs only a decorative function and not static.

The panels are an alternative solution with respect to the walls real stone since they can be employed for various uses, installed in different environments without the requirement to erect massive walls species there where it needs only a decorative function and not static.

Suitable for both indoor and outdoor, for living rooms, kitchens, bedrooms, taverns, fireplaces and even bathrooms, for cladding of external walls, corners with spectacular swimming pools, garage, shops, public activities, exhibitions, theater and cinemas.

The plates are also used to cover the ceilings, maybe alternating with wooden beams, to create a cozy atmosphere with a rustic flavor and to improve the acoustics being a compound of the good insulating capacity.

In short, a truly versatile product to be appreciated in all the specificity both aesthetic and technical-mechanical.

79806 REGISTERED USERS