Clay plaster in self costruction

Post from EditorialsThe clay plasters can be made by buying ready soil or reusing the excavated ground from the work site, with the right amount of sand and straw.

Clay plaster with recovery dug soil

It is not compulsory for those who want a clay plaster in their homes to necessarily buy the material that they will apply on the walls (LaCasaPensata.info).

Since it is soil, it may be convenient to reuse the excavated earth inside the construction site, accumulated for example following the construction of a crawl space.

Or you can ask to use the land from a nearby construction site which in turn would avoid the cost of removal and disposal of the excavated soil.

The conditions are obviously that you are in the country side or at least in a not very built up area and above all that the land is not contaminated.

When is the self-construction convenient

Participating in self-construction building of your own home is something that people who got the chance to experience, always remember with pleasure and pride. Of course there are many difficulties for those who are not at hand with the profession; with self-construction times are long and as well are the sacrifices, but generally the dedication and perseverance prevail.

The excavated soil of recovery to be used for the realization of the plaster will have to be carefully selected and sifted, so if you want to keep down the costs the only solution is to personally hand work with the self-construction.

Paying people to sift the soil to use separating it from the stones would be in fact more expensive than buying some big bags of earth, failing at this point the economic viability of the operation.

The phase of the plaster in the yard

During the execution of the plaster the look of the work site changes dramatically, it passes from the rustic look of the brick walls of planks with a consistent look and no more traces of the visible plants.

Regarding the aesthetic, a plaster made clay looks generally softer and imperfect compared to a traditional plaster made with screeds on metal runners.

Rounded edges and corners not perfectly square, but this is its beauty.

Preliminary checking operations

Before proceeding with the realization of the mixture of the plaster to be checked whether the available soil is suitable for the purpose, in such a way as to determine with empirical evidence the amount of present clay.

Before proceeding with the realization of the mixture of the plaster to be checked whether the available soil is suitable for the purpose, in such a way as to determine with empirical evidence the amount of present clay.

A procedure may be the cup. After kneading the earth with a little water must create a small cup and fill it with water. With this experiment it is possible to evaluate the presence or not of clay and bentonite in the earth, considering the amount of water that the cup is able to absorb before it breaks.

Another proof is that of the cigar, and serves to assess the degree of plasticity of the earth, however, the presence of a percentage of silt could mislead it so it is best to perform more types of evidence.

The clay acts as a colloid because it has small granules (diameter less than 3.9 micrometers), the silt instead is located in an intermediate position between sand and clay, and it promotes plasticity but it doesn't paste.

Finding the right mixture of soil, sand and straw

Once these and additional tests, such as sedimentation and, for the less squeamish, the test of the bite, one may proceed to prepare different mixtures of clay, sand and straw, so as to determine the ideal composition specific for that type of Earth.

The sand must be preferably of the river, with grains fine and rounded, as sharp edges could make difficult the processing by the trowel, while the mixture should be done dry by adding water little by little.

First you need to prepare the support: a good way is to dilute a lot of water a bit of soil to obtain what is called slip and spray it with a brush on the wall to be plastered.

The slurry will help the adhesion of the plaster to avoid that at a later time this can detach from the wall.

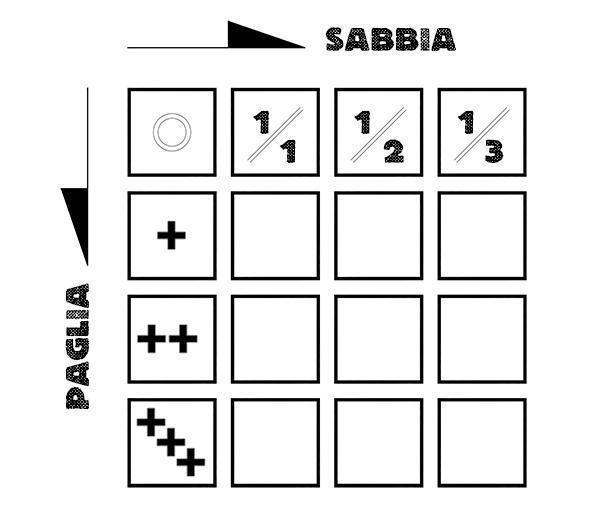

Once you dry the slip one begins with the tests, creating a grid and from time to time by adding sand or straw, depending on whether one moves horizontally or vertically along the grid.

It is advisable to start with the straw, because it takes longer to dry, after which we'll stick with the sand and finally descend diagonally with sand straw.

These tests are used to determine how many parts of sand and straw are needed for the non-plaster cracks and remains uniform.

Obviously for the base of the plaster you need thicker sands, leaving the finer grain sizes for the finishing coat.

Within the layer of base fill is best to drown in the dough, leaving a net of jute protrude some tack, this will serve as a structure together with the straw and will ensure that the plaster does not fall off the wall.

Finishing soil plaster

The finishing coat is definitely the stage more fun and artistic, being able to add the charges to second the taste and the effect you want to achieve.

It defines everything that charge is added to enrich the aesthetic look of the plaster, such as oxides or colored fragments of mother of pearl or straw, that once on the wall seem golden scales when illuminated.

Where to learn how to make a plaster with excavated earth

What better place to learn how to make and apply a plaster with clay of dug earth than in a construction site in the open countryside.

The association Bioecoservizi work between Milan and Reggio Emilia and organizes wokshop construction sites for which offers consulting services and where you can learn how to make a plaster with a land truly at zero distance. The photographs in the article were taken on the occasion of a seminar organized by the association.

Alternatively you can find out about the activities proposed by eco-villages scattered throughout Italy, such as the ecological village of Granara.

Generally courses covering the earthen accompany those dedicated to the construction in straw, the important thing is to be willing to get your hands dirty and experiment with creativity.

79870 REGISTERED USERS