Wood plankings

Post from EditorialsThe great versatility of a product such as panels of wood strips to make structural elements and furnishings, getting strength and lightness.

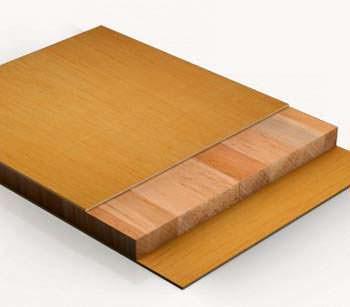

Panels of wood plankings

Wood is the building material better known since the dawn of human civilization, with the wood were built for centuries the most diverse and prestigious works, arrived to the present day in terms of resistance to some extent astonishing, in relation to the past years and snares of the time to which they were submitted. Today in the full technological development, even if some special materials, innovative and in many ways revolutionary, have appearead on the horizon, the wood is still used with a greater attention to its mechanical properties, heat insulating and structural, in order to carry out works including large complex structures.

Today in the full technological development, even if some special materials, innovative and in many ways revolutionary, have appearead on the horizon, the wood is still used with a greater attention to its mechanical properties, heat insulating and structural, in order to carry out works including large complex structures.

The industrial sector that deals with the production of the wood for construction, provides every type of essences assembled in such a way as to highlight the aesthetic characteristics, while also increasing the mechanical strength.

One of the most obvious examples, used in all areas of construction is represented by the planking panels, available in different variations.

The plankings are available on the market in the form of panels of size 122*250 cm normally with thicknesses ranging from 14 to 30 mm; there are companies that produce even larger panels for specific types of work in the field of furniture.

The panels made of wood plankings, are constituted by a central structural part formed by gluing together strips of wood of various essences, which represents the base of the different products obtainable by coating the same with layers of veneer of different essences. Normally the strips forming the core of the panel, have a variable width and can reach the maximum of 33 mm.

Normally the strips forming the core of the panel, have a variable width and can reach the maximum of 33 mm.

When the panels made of wood plankings are constituted by strips assembled together taking care to arrange them with the orientation of the fibers in a parallel manner, but with force lines alternate with overlying coating made in plywood panels, is realized a panel generally known as plywood board.

Wood plankings to build in safety

The panels described and all those obtained using different essences between them, are assembled with adhesives very safe with low formaldehyde emission and can therefore be employed for the realization of countless objects of furniture and service. The construction of a staircase, can be safely carried out by using the steps in beech wood strips with a thickness of 5 cm, without any further coating of the soul wood strips but simply treating the same with a matte varnish to protect the structure elements such as dirt, water and so on.

The construction of a staircase, can be safely carried out by using the steps in beech wood strips with a thickness of 5 cm, without any further coating of the soul wood strips but simply treating the same with a matte varnish to protect the structure elements such as dirt, water and so on.

The wood strips provide great operational advantages to those who use them for the construction of furniture, various items of furniture such as doors, shelves, paneling carriers, bookstores, this versatility comes from the fact that the material of which it is composed is workable.

Cuts, punctures, assemblages mediating screws, are easy and of practical realization, in particular the sealing of the tight wood screws, it is particularly suited to realizing modular structures subject to subsequent disassembly, without running the risk of being in below with parts not more usable because of the disintegration of the assembling holes.

The mechanical properties and resistance of the wood strips are known for centuries, just think that in ancient Egypt, it was already in use to achieve the finest furnishings or some ornamental elements in support of the residences of the pharaohs during their lives, and employ the same material in furnishing also the final resting place inside the pyramids.

Today, the use of laminated wood in the field of decor is very frequent, thanks to special products such as hardboard superlight panels.

Superlight plankings

The super lightweight panels, are characterized by a very low specific weight, and when used in the version with layered coating, they are coated with very light but resistant essences, one of the most used timber for the realization of the soul of a light panel is the Albasia wood.  The Albasia is an oriental wood very resistant to loads but with low specific weight, it can be observed commonly in stores where there are ethnic furniture, statues, etc.., made in this kind of wood.

The Albasia is an oriental wood very resistant to loads but with low specific weight, it can be observed commonly in stores where there are ethnic furniture, statues, etc.., made in this kind of wood.

Its use in place of the traditional and our own woods such as poplar, allows you to create very durable, lightweight panels, particularly suitable for the production of hinged structures subjected to constant stress.

One example, is represented by the doors in general, whether they serve to make the bases or cabinets of a kitchen, whether they serve to make doors or compartmentalization of different types, thanks to the reduced weight in relation to their size, are unable to significantly reduce the work of all the metal parts that allow movement such as hinges etc.. and all this for the benefit of the overall strength of the cabinet.

A structure such as a door or another, made of light strips can be easily finished in the ways and dimensions you like, without any problem, something not possible with other structures that are not easily read while being equally workable, such as panels made with a core of honeycomb cardboard and plywood sheathing.

Finally, we must not neglect the great advantage of not having to proceed to the edge of the cut pieces all in favor of the desired subsequent construction operations.

79870 REGISTERED USERS