Movements of folding beds

Post from EditorialsTo correctly choose which type of folding bed is better for the home is useful to know the movements on the market and know well where to turn.

The new generation of space-saving folding beds

The attention towards folding beds has changed dramatically since a few years ago; in the past people resorted to folding beds only when receiving guests, but now because of the houses with surfaces smaller and smaller, the new generation of folding beds are used in everyday life to quickly turn a living room into a bedroom or to give to a cramped room the space you need for playing.

What changes primarily between a dated folding bed and the new space-saving beds is the quality of the sleep, as the latter are now equipped with spring, memory or latex matrasses, lying on sturdy wooden orthopedic slats.

Between a space-saving folding bed and a fixed traditional bed nothing changes as regards the quality of sleep, provided of course that you will buy quality products.

The limits of industrial folding beds

We have to have luck, because a piece of furniture or a convertible folding bed mass-produced on an industrial scale are actually space saving.

Sometimes because of a few centimeters some precious space can remain unused but completing it with additional modules realized specifically can result in some cases more expensive than a solution totally tailored carried on by craftsman.

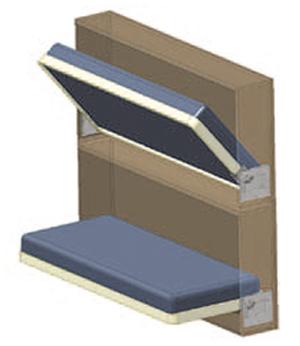

Movements and mechanisms for folding beds

Knowing the movements and mechanisms can have greater control over the quality of the components of the folding bed, so as to be able to address the craftsman in charge of building the piece of furniture or otherwise critically assess an industrial product, also due to the that solutions to complete package mass-produced and proposed a high price in furniture stores sometimes use standard mechanisms on basic model.

The products by Pozzoli have a great visual impact, made of wrought iron and painted, they have a specific weight and therefore considerable mechanical strength and wear resistance.

The movement of the bed can be both manual and automatic, in both cases the descent is braking and soft thanks to the robust pistons in gas operation.

In the versions sofa-bed the panel network with a thickness of 4.5 cm it is lowered gently up to 25 cm from the ground, turning simultaneously to the sofa seat which falls into the structure through an independent movement.

The tipping necessary to hold the front panel, the network and a mattress of 21-24 cm range from 35 to 37 cm, in such a way that it is possible to close the bed also with sheets and duvet.

Isram alongside with the products for the domestic area has also excellent solutions for marine and hotel sectors, as well as offering traditional networks in wood and metal networks also entirely made of beech wood.

Generally nets made by Isram are not directly panelable, necessitating the mechanism for the movement of the legs of a space of about ten centimeters between the network and the panel. This allows a greater ventilation of the mattress beneath the slats but at the same time, the depth of the body more important, starting from forty centimeters.

Particular attention deserves the network then the container provided with movement to facilitate the operation of making the beds.

The recommended height to make the bed is about 60-65 cm, in such a way as not to be forced to lower and maintain the back. Sitting on a bed higher than 60 cm can be difficult, however, in relation to the height of the person, it has therefore been patented by Isram a special system of lifting network and mattress. If the presence of the support legs for a space-saving folding bed was a problem, Gilardi realizes a compact mechanism (we are talking about the series MLA), which engages between the wall and the shoulder of the body that incorporates the network can be paneled.

If the presence of the support legs for a space-saving folding bed was a problem, Gilardi realizes a compact mechanism (we are talking about the series MLA), which engages between the wall and the shoulder of the body that incorporates the network can be paneled.

The network is thus self-supporting and does not need the beds supports working exactly like a shelf, therefore suited to both the domestic sector and the naval and campers.

The main advantages you have by using this type of motion are:

- The possibility of a reduced thickness of the containment bin (only 29 cm if it matches the network to a spring mattress of 14 cm)

- Freedom in positioning the network to a desired height, then possibly over the seat of a sofa or container drawers for blankets and pillows, made possible thanks to the absence of the otherwise necessary supports on the floor.

Once you clear the kind of movement that fits your situation, you can contact a specialized carpenter's shop that can carry out the containers and eventually completion modules of the wall unit. In this way you will match the quality of materials of an handcrafted custom-made piece of furniture, generally wooden strips and not particle board, to the functionality of the mechanisms and movements space-saving.

79868 REGISTERED USERS