Wooden joints

Post from EditorialsThe joints are a fundamental technique for assembling the wood here is the key, and how to choose each time the type best suited to the job.

Combine the wood with the joints

Snap-fit unions give particular strength and stability to the wooden buildings. The precision of their preparation is critical because the pieces that fit together perfectly and help enhance the function of the glue, especially if it is vinyl glue that is not very suitable to fill possible gaps caused by an inaccurate combination of the pieces to be joined.

Snap-fit unions give particular strength and stability to the wooden buildings. The precision of their preparation is critical because the pieces that fit together perfectly and help enhance the function of the glue, especially if it is vinyl glue that is not very suitable to fill possible gaps caused by an inaccurate combination of the pieces to be joined.

There are some combinations that do not require glue, but which base their seal on the weight or the fact of being part of a sturdy structure, bound also in other points. But, in general, the rule is that the wider are the bonded areas and the greater is the strength.

A mortise and tenon joint, for example, is generally more robust than an interlocking corner mainly because, the main faces in contact are four instead of two.

Decide which joint

You have to identify exactly what a joint must provide: it is a fundamental support, or it just need to give more strength to the whole? Strength, appearance, ease of cutting and construction are the fundamental elements of any joint.

The joint will be compressed or will be placed in traction? Make sure you can counteract the stresses that will be created: this will allow you to avoid the construction of a joint more complicated than necessary.

A wooden joint reduces the size of a piece to 80x80 mm in a 80x40 mm.

You then need to be very sure that your choice justify any reduction in size and thus in strength. Also, make sure that the pair you have selected is not less resistant of another.

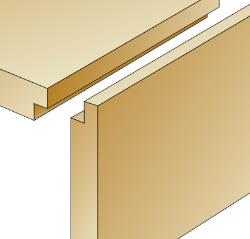

The wood

The wooden joint is one of the most simple and classic. Used for connecting strips of varying section so that the overall thickness always remains the same. It is about making, on both parts to be joined, a downward square of the width of the piece to receive and depth equal to half of its thickness. If the cut is very precise the fit is virtually unbreakable.

Joints and slots for frames

Unions to make frames are always structural so are designed to withstand stresses and tensions. We make them, in general, with strips and wooden boards both soft and hard. The most complex joints, the numerous intersections and the repeated overlaps require, however, always of the cuts with relative weakening of the piece of wood.

Unions to make frames are always structural so are designed to withstand stresses and tensions. We make them, in general, with strips and wooden boards both soft and hard. The most complex joints, the numerous intersections and the repeated overlaps require, however, always of the cuts with relative weakening of the piece of wood.

The joint is stronger than the one that leaves more intact the workpiece. After these preliminary considerations, you can put your attention to the various types of joints to choose the one that seems best suited to your work.

Mortise and tenon

Among the joints most useful (and known) is the coupling between the tenon and the mortise. It is, in practice, a male tooth and female cavity which achieve an very robust joint, especially if the cuts are precise. The tenon may be variously shaped: narrower and thinner than the piece from which it is derived, or only narrower, or only thinner.

It may be at the center of the head of the part or leaning against one of its edges. The solutions are many: it must be adopted the one that, at the time, is more useful.

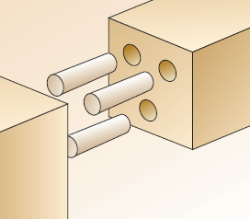

Fixing bores

A system extremely simple and widely used to connect two wooden parts without having to perform special processing is to use the cylinders of wood, called plugs which are inserted into holes made on the components to be connected and perfectly coincident. The only critical phase of the work is precisely that to match perfectly the holes in the two pieces. To overcome the difficulties using special accessories called markers cap. One proceeds thus: are practiced, on one of the two pieces of the holes needed to accommodate the plugs in the appropriate diameter.

The only critical phase of the work is precisely that to match perfectly the holes in the two pieces. To overcome the difficulties using special accessories called markers cap. One proceeds thus: are practiced, on one of the two pieces of the holes needed to accommodate the plugs in the appropriate diameter.

The markers are inserted in the holes that are equipped with sharp points, and then approaches the second piece in place and it is pressed against the markers that leave a visible sign, which serves as a track for the holes that must fit together. The union is achieved by wetting plugs with glue and inserting them into the holes of the two pieces that are then pushed together and put in a vise.

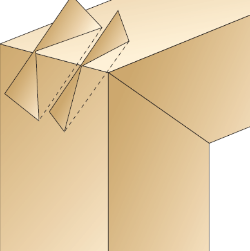

The tab for frames

To realize very quickly framing of paintings or other frames you can adopt the technique of cross-tab. It is cut at 45 degrees both strips that concur in the junction, in order to realize a connection of 90 degrees.  This connection may be simply glued and have already kept a discreet endurance but you can easily reinforce running (with ripsaw) alongside its two cuts on the corner that has been formed with the combination of the two strips.

This connection may be simply glued and have already kept a discreet endurance but you can easily reinforce running (with ripsaw) alongside its two cuts on the corner that has been formed with the combination of the two strips.

The cut should be perpendicular to the junction line of the strips. In the groove left by ripsaw inserted two thin tabs of wood and glued them to you.

When the glue has hardened, with a fine-toothed blade, cut wire protruding parts of the surfaces of the tabs. In this way the angular connection is greatly reinforced.

The dovetail

The dovetail type is undoubtedly the most classic interlocking and aesthetically valid, but it is quite difficult to achieve.

The glue acts as a stabilizer but the union is strong in itself. Because the cutting of the teeth and grooves is quite problematic, it is convenient to use special drilling templates which are fixed on the edges to be shaped. In the guides of the masks will slide special cutters (operated by the drill) which practice the carvings with absolute precision.

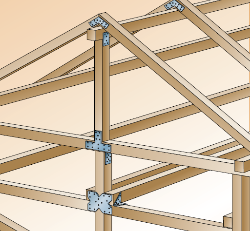

Metal Joints

If you want to achieve very robust unions on battens or wooden joists of indents may be less suitable than other solutions. The joints, in fact, have particular strength and toughness when they are reinforced with glue. In structures of a certain size, where the levers and tensions are significant, the glue does not exercise an important function. That's why it makes sense to use special metal joints that deliver extremely robust and stable connections between strips of varying section.

In structures of a certain size, where the levers and tensions are significant, the glue does not exercise an important function. That's why it makes sense to use special metal joints that deliver extremely robust and stable connections between strips of varying section.

In the market are very different development joints that allow the creation of unions in X, T or variously angled head, along the body, on a plane and also between more than two elements competitors. These joints have many holes on the wings that make them up to let through nails or screws holding the wooden elements to the joints themselves. Other types of joints do not have a defined link function but only reinforcement.

79733 REGISTERED USERS