Wax finish on wood furniture

Post from EditorialsAfter painting, wood furniture require a protective layer: one of the most popular materials for the finishing is wax, durable and easy to apply.

Wax finish

The restoration of a piece of furniture finishes by applying on its surface a finishing product that can enhance the beauty and protect the wood. The finishes that can be performed are different. Some are classic (wax, shellac, etc.), Some are modern. Let these to professionals and we can deal with those that are most suitable for the enthusiast, especially the wax finish. The wax finish is certainly the oldest and the most widespread. It has the great advantage of being easy to perform, to protect the wood for a long time and be very nice. The wax finish is recommended when a piece of furniture was originally waxed and you want to keep its characteristics . The wax is applied after it has been properly prepared or using a product ready for use.

The wax finish is certainly the oldest and the most widespread. It has the great advantage of being easy to perform, to protect the wood for a long time and be very nice. The wax finish is recommended when a piece of furniture was originally waxed and you want to keep its characteristics . The wax is applied after it has been properly prepared or using a product ready for use.

The application can be done with a brush, with soft bristle brush but with a pad. The latter system, however, is to be reserved for pieces of fornitures that have large, smooth and continuous surfaces, without moldings, incisions or reliefs, since the pad does not fit well. In any case, the wax must be passed over the entire surface of the cabinet without leaving any part uncovered and without creating accumulations. Do not charge too much the brush to avoid creating drips.

After applying the wax carefully wait a few hours during which the product dries and is well absorbed by the wood. At this time, pass on the treated surfaces a warmed cloth.

Working the surface calmly, but with energy, will increase the brightness. If the wax is too dry, pass on the forniture a woolen cloth soaked in wax more dilute than that used previously, then wipe with a warm washcloth. The treatment can be repeated.

The wax

The wax that is used for the finish of the cabinet is beeswax bee. A time it was available only in solid tablet, is now also ready for application in different formulations. The classical preparation of the wax to finish, however, is this: chopped a limited amount of wax (eg. 100 g) and place in a container by adding 1 liter of turpentine. Heat the container in a double boiler, stirring occasionally (be careful: the turpentine is very flammable). When the wax is completely melted is ready for use. You can fill a container and close it tightly again, to use the wax when necessary. The ratio of wax and turpentine can vary according to specific needs: you can identify the different blends to suit every type of work.

You can fill a container and close it tightly again, to use the wax when necessary. The ratio of wax and turpentine can vary according to specific needs: you can identify the different blends to suit every type of work.

In general, the harder woods require greater dilution while those sweeter want a more concentrated solution.

The wax thus prepared can be mixed with various dyes to obtain a hue well determined.

The pad

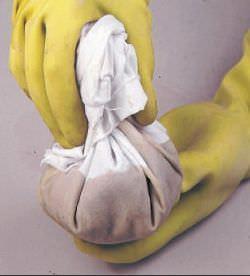

The pad is a means of applying the paint (as well as the liquid wax) very old and, in some ways, unsurpassed, thanks to its capacity (if used well), apply thin layers of paint to a high accuracy. Here's how to prepare:

1) To obtain a pad of medium size, take a cotton swab (or felt) as large as an apple.

2) Sustain the middle of a cotton cloth 15x15 cm.

3) Fold toward the center of the four corners of the cloth so as to incorporate the cotton forming a bag.

4) Fold the edges back.

5) Put your bag in the middle of a linen canvas 25 x 25 cm.

6) Form a new bag. The characteristics of the pad will vary according to the use which it is intended: its size is determined in relation to the surface to be machined: for a large table is convenient to use a big pad in order to perform a smaller number of passes, if instead you have to treat small surfaces, prepare a rather small pad. The pad is prepared by wetting the swab inside and close well the tissue of containment.

The characteristics of the pad will vary according to the use which it is intended: its size is determined in relation to the surface to be machined: for a large table is convenient to use a big pad in order to perform a smaller number of passes, if instead you have to treat small surfaces, prepare a rather small pad. The pad is prepared by wetting the swab inside and close well the tissue of containment.

Then, holding the pad, sliding it on the wood pressing least in the beginning and more towards the end. The application pad consists of a continuous overlay of thin layers of paint. The pad , between a processing step and another, can be stored hermetically closing it in a jar, for reuse without having to make a new one for each application.

79734 REGISTERED USERS