Tool box, how to build it

Post from EditorialsThe construction of a toolbox lets you create a box tailored to your needs and, accordingly, functional and well organized.

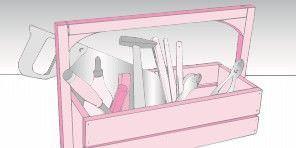

Build a toolbox

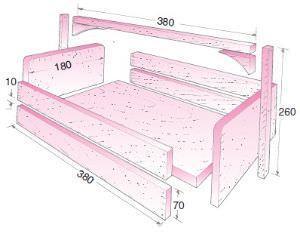

Practical and easy to make, a DIY tool box is very resistant and allows you to always have on hand the necessary tools. Use pine or fir (thickness 20 mm) also of poor quality, provided free of knots. Put the pieces together with self-tapping screws bronzed 25mm, strengthening unions with glue. Strengthen the joints of the handle with two shaped triangles, screwed and glued.

Put the pieces together with self-tapping screws bronzed 25mm, strengthening unions with glue. Strengthen the joints of the handle with two shaped triangles, screwed and glued.

With medium-fine sandpaper smooth the sharp edges of the handle so you can easily grab the box.

In place of the grip you can also use a copper rod. The several pieces, before assembly, must be painted with protective paint. Start the assembly from the bottom and fixing the two end walls, then screw the four elements that make the sides up.

Start the assembly from the bottom and fixing the two end walls, then screw the four elements that make the sides up.

Last, set the handle supports. Finally fix the handle itself.

You can also divide the interior space to have several rooms that allow you to keep more tidy the tools and the small metal components.

If the box is intended to contain also heavy objects, reinforce the bottom with metal brackets by screwing them to the side walls.

The editorial staff recommends:

The tools for the toolbox

In order for the tool box to be actually functional, are not important only its structure and its solid construction, but also what it will contain. Deciding the composition of the toolbox is a very important operation, which can be performed already during the early stages of the design of the box, so as to achieve it tailored to what it will contain.

The perfect toolbox will be the one containing the generic and fundamental tools, along with those that might be less common, but specific to the types of jobs that you expect to carry out frequently.

The most part of the tools will be chosen according to your needs, for a personal toolbox that will meet your needs.

Among the fundamental tools to be included within its box, screwdrivers of various sizes and cross cutting can't be missing, a set of keys of various sizes, open and polygonal, and a set of pliers.

Within the box there will also be nails of various sizes, screws, bolts and dowels: all tools that may be useful for many types of work. In the box you should put a meter to make measurements, a cutter, one or more hammers, work gloves, mask and protective goggles, a level, a torch. If the box is spacious enough, here will be placed a small cordless drill with drill bits.

In the box you should put a meter to make measurements, a cutter, one or more hammers, work gloves, mask and protective goggles, a level, a torch. If the box is spacious enough, here will be placed a small cordless drill with drill bits.

Scissors can't be missing, resistant enough to cut different types of materials, as well as the tape of various types. Even glue and sandpaper are elements of frequent use, which therefore should never be lacking in a well-stocked toolbox.

Organizing space

When preparing the toolbox, the provision is important to ensure efficiency: using small compartments and dividers allow you to organize the space in the best way and always have an eye and hand all you need, without having to waste time in search of the smallest elements.

On the bottom you can place the bulkier tools that you don't use so frequently: the ability to create a double bottom allows an optimized use of the spaces of the box and facilitates the maintenance of order. Each tool, however, must have its own well-defined space, in such a way as to be always detectable in seconds and thus facilitating the maintenance of cleanliness and order. For smaller objects, such as screws and nails, it may be placed in plastic bags within the individual compartments, to have the certainty that each element remains in its place.

For smaller objects, such as screws and nails, it may be placed in plastic bags within the individual compartments, to have the certainty that each element remains in its place.

Similarly, the keys or the tips of the drill, as well as screwdrivers, can be kept together by an elastic band of appropriate size.

In this way you can count on the perfect arrangement of each object despite the frequent movement of the box.

Organizing in a rational manner the box, not only simplifies the work, but will prevent the tools, in contact with one another, to be damaged and will prolong their lifetime thereof. As well as individual tools, even the various compartments of the box will be periodically emptied and cleaned.

79734 REGISTERED USERS