Perfect holes with the drill

Post from EditorialsWith proper tools and some changes you can drill easily and accurately any type of material here is some advice for the perfect hole.

Drill holes in the plastic

For drilling Plexiglas and plastics generally we can not use a normal drill bit for metal, as this would create a hole of irregular shape. To overcome this drawback, the chamfered end portion of an old drill bit to make it less sharp and use it to pierce the plastic. The hole will come out perfectly circular.

Drill holes in the glass

When drilling the glass with the drill it may happen to the material to split due to the considerable force exerted.

When drilling the glass with the drill it may happen to the material to split due to the considerable force exerted.

To avoid this rick, place on the glass surface a ribbon of plaster in the shape of a circle and pour a certain amount of trichlorethylene in the cavity thus obtained.

Pierce the glass by placing the spearhead drill in the space delimited by the plaster: the presence of trichlorethylene prevent glass breakage and allow you to get a perfect result.

Perfectly round holes

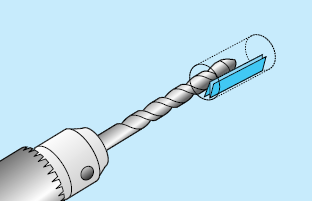

When you have to drill a metal sheet and can not really get round holes, even with the drill press, try to pre-drill with a little bit (3-4 mm diameter), and then move the big one interposing a cloth of wool or cotton (wide and about 6-8 cm long and eventually folded a couple of times) letting laps together at the tip holing.

Hole larger than the point

To obtain a larger hole on the part, with respect to the tip of which you have, introduce a piece of cloth or paper of aluminum in the hole, so that standing between the tip and the wall of the hole itself.

To obtain a larger hole on the part, with respect to the tip of which you have, introduce a piece of cloth or paper of aluminum in the hole, so that standing between the tip and the wall of the hole itself.

In this way a sharp tip (the one opposite to the cloth) will work as a reamer, widening the hole.

Wanting to further increase the diameter, you can use a piece of cloth thicker or introduce one folded back on itself. The amount of cloth to be introduced must be suitably adjusted so that the groove of the tip is filled well, to avoid vibration and the consequent deformation of the hole. Obviously you'll have to work with the drill very slowly.

Remove flaws

On the market thre is a tool to remove the flaws from the holes, consisting of a finned cone with a 90° opening. It is an expensive tool, which can be replaced by a drill bit diameter rather large (ideally 1012 mm Ø) which will apply a handle to the file and to which, moreover, will modify the cutting edges at 90° to the grinding wheel.

Dust, the enemy of the drill

Dust can seriously damage the drill, until it becomes unusable or even dangerous.

Dust can seriously damage the drill, until it becomes unusable or even dangerous.

Any dusty mechanism, in fact, malfunction due to friction, and because electric motors, within them, must always be clean, to avoid overheating, failure, shock.

To avoid such problems always place the drill in a nylon bag that will prevent sawdust and grinding dust to creep inside.

The editors recommend

The power of the drill

In choosing a drill, you must consider many variables and assess whether the characteristics of the product are able to meet the specific requirements of use that you think will occur more frequently.

In addition to choosing between the different types of drill (electric drill or cordless drill, or driver easy drill ...), you can sometimes find it difficult to interpret the information on the technical features that allow us to choose between different instruments of the same type.

In addition to choosing between the different types of drill (electric drill or cordless drill, or driver easy drill ...), you can sometimes find it difficult to interpret the information on the technical features that allow us to choose between different instruments of the same type.

Or, it can happen to not pay enough attention to information considered incidental.

After choosing the desired type of drill, one of the first factors to consider is the power of the device. A common mistake, in fact, is to consider the power as described on the package power actually available to the spindle. In reality, the values reported are usually referring to the power of absorption of the drill in the conditions of normal use, while the power of the motor corresponds to half the value reported.

For a quality drill

There are certain characteristics that can be attributed to quality drills and make it practical and versatile. Now widespread is the percussion mechanism, which allows the instrument to crush even compact materials. This is because the addition of the percussive movement to the rotary facilitates the crushing of the material and its drilling.

Added value is given by the mechanical change of speed, found in the tools of the medium - high. Thanks to this function, the drill is able to exert, at low speed, higher power drive that facilitates the drilling of materials also difficult to process.

Finally, the drive speed makes it the most versatile tool acting on the spindle: reducing the speed, the drill will be more effective in metal drilling, while increasing the speed of the tool will be made more suitable for woodworking. In this way, with a single drill can also be executed in a satisfactory manner many types of work.

79734 REGISTERED USERS