House ready in 4 days

Post from EditorialsThe Pop-up House is a prefab house designed by Multipod Studio; it can be built in just four days and it is environmentally friendly and completely recyclable.

Pop-up House, an ecological house ready in 4 days

Imagine a house that is constructed using only a screwdriver and prefabricated panels, in less than a week. It is not a toy house, but a Pop-up House, a real home.

Pop-up House is a prefabricated house the work of the design of the French study fom Marseille Multipod Studio, you can build it in just 4 days of work and using only a screwdriver. In addition, it is also an ecological house and completely recyclable.

The prototype was designed to be assembled easily and quickly by simply following the recommendations of an instruction booklet. In fact the house is made from a series of prefabricated elements in wood and insulating materials, with joints designed to be connected as if they were Lego pieces.

This will reduce the cost and time of construction, while costs for materials may vary depending on the thickness you choose, but the average price for erecting the roof, walls and floors is around 200 euro per square meter, so it is of very affordable rates.

At this cost, including materials and construction of the structures, are then added to those for waterproofing, exterior finishes, interior finishes, electrical, plumbing, heating, etc..

In fact, the French team has just designed to meet the needs of a modern family with regard to the house: energy efficiency, environmental sustainability, speed of construction and, of course, cost.

Features of a Pop-up House ready in 4 days

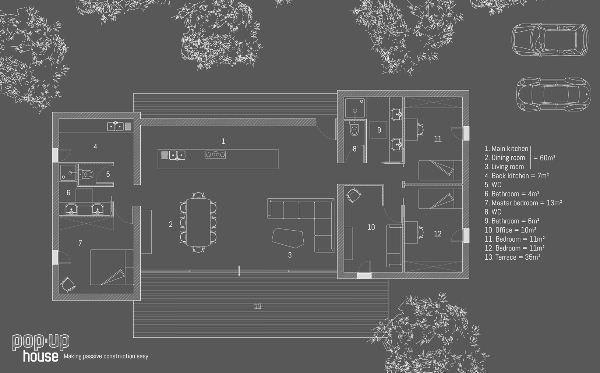

The first prototype, built in a pine forest in Aix-en-Provence, in southern France, is a house of 150 square meters, but there is also a version of the study from 70 square meters.

The assembly of the DIY modules has been patented and has been designed to make possible the construction of the house even by people with no special skills.

Among other things, a part of the assembly can also take place already in the laboratory.

After several studies it was decided to use wooden panels of LVL, Laminated Veneer Lumber, a product made with thin layers of wood, high-performance, which therefore guarantees excellent mechanical performance and is characterized by a particular fire resistance.

The panels are covered with EPS, ie polystyrene foam, a material that provides thermal insulation absorbing and reflecting part of the thermal radiation.

The EPS used for this house is gray because it contains graphite, and it has a capacity of insulation, with the same density, 20% higher than normal white EPS.

The EPS can have a density ranging between 10 and 40 kg/ cu.m. In this particular case we opted for a product having a density of 30 kg/ mc, which allows you to combine good level of insulation with a certain lightness and resulting in greater ease of handling.

In the Pop-up House, however, can also be used other insulating materials, as long as low-density fiber boards as wood, cork panels foam, rock wool, polyurethane foam, etc..

And it is the high thermal insulation, with a U-value of 0.11 W/ mqK, which makes the Pop-up House a passive building. In fact, the house is so well insulated and the weather outside does not interfere with the internal environment, so that heating and air conditioning in summer become almost unecessary. In fact, the use of the heating system is only needed for short periods of the year and for a few hours, at least for the Mediterranean latitudes.

The assembly of wood paneling and insulation material can occur in two ways: with long screws or glue.

The recyclability of the Pop-Up House is easy due to the possibility of disassembly, which is nothing more than the inverse of the assembly phase and is equally simple, and therefore to the possibility of reuse 100% of all the material, both the wooden one that the insulator.

To recycle the house, however, you should choose the assembly screws, otherwise the glue will dirty the panels that could not be reused.

Inside, the passage of the facilities is ensured by the slots on the panels that make up the walls and floor.

The finishes, both internal and external, may be chosen from among several options.

79810 REGISTERED USERS