Epoxy filler

Post from EditorialsThe epoxy filler used as filler between tiles and adhesive coating, has excellent characteristics including high hygiene and resistance.

Stucco in the construction industry

Stucco is a mixture of fine gypsum, lime or cement used in construction for the covering and decoration of walls and ceilings. Generally it is used to give a more pleasant appearance to rough surfaces such as concrete, wood and metal, or as a filler for holes and joints between the tiles and to hide defects of a surface. The stucco, due to its pasty consistency is rather subject to rapid drying.

The stucco, due to its pasty consistency is rather subject to rapid drying.

Its composition can be highly variable; sometimes are added acrylic or glass fibers additives to increase the strength properties and workability.

Historically the stucco consisted of a mix based on slaked lime, calcium hydroxide and powdered marble. This compound looking quite workable, could also be molded to create three-dimensional figures and statues.

In fact the Baroque and Rococo architecture have made extensive use of the stucco in buildings and churches, to build lintels, cornices between walls and ceilings. This material also create an extension in the three-dimensional paintings and reliefs in the trompe l'oeil. Some mixtures, made mostly of gypsum, not tolerating moisture are suitable for internal use, while others are used for decorations exposed to the elements.

Some mixtures, made mostly of gypsum, not tolerating moisture are suitable for internal use, while others are used for decorations exposed to the elements.

The stucco mixed with resins and glues is used in the building industry also to fillet joints between two or more architectural elements or as a pasty compound, to be used for smoothing walls in plasterboard or plaster coated.

Among the various types we also find the epoxy grout.

The epoxy grout: what it is and where it is used

The epoxy grout is a product used mainly to heal joints of high humidity areas covered in tiles, such as bathrooms and kitchens.

It sas a much tougher consistency than the normal stucco and for this reason is more difficult to spread, but it has many advantages, for example:

- It doesn't get dirty, then it keeps the color of the chosen joint

- It prevents the formation of mold and mildew in the joints.

Although the cost is slightly higher than conventional adhesives and fillers, the epoxy filler as an optimal solution, to put in place both coatings floors.

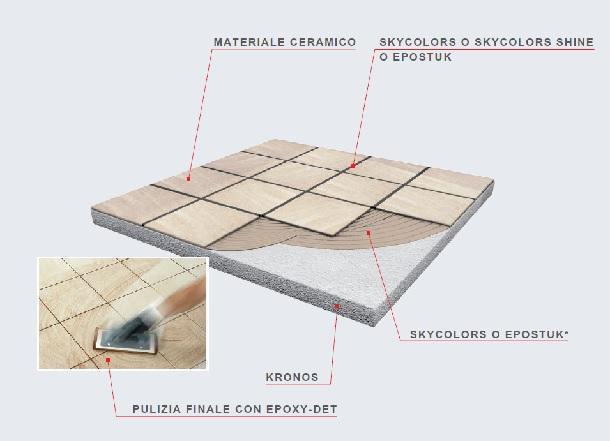

A company that offers epoxy grout in all its variations, so as glue and as a filler with annexes products for cleaning after laying, is Technokolla SpA., which offers to its customer products for all needs and shows through schemes very simple attachments to products, the mode of installation of the same.

Generally, when making the joints in a floor or in a coating, after putting in place the tiles with suitable spacers, you will have to lay the epoxy grout with a rubber trowel. The plastered area, still fresh, must be soaked in clean water; this is because the epoxy filler has a rather pasty consistency.

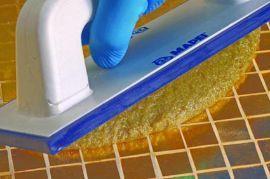

To make sure that the product is evenly distributed into the joints, it will be necessary to level the surface with a soft wet felt, taking care to clean it frequently with plenty of water.

Here you will need to clean the surface again with a fresh grout spreader tool, to remove the excess product and finally, the cleanup phase of the floor or wall tiles must be completed using a soft sponge very humid.

Another company that manufactures epoxy products is Mapei that the product Kerapoxy, a two-component acid-resistant mortar of epoxy type quick-setting, solves the problem of filling and bonding of ceramic tiles, stone elements, asbestos cement, concrete and other building materials.

Its uses are manifold, including:  - Plastering of industrial floors and walls and others, that require a high level of hygiene, and mechanical resistance to attack by acids

- Plastering of industrial floors and walls and others, that require a high level of hygiene, and mechanical resistance to attack by acids

- Filling of swimming pools, in particular tanks containing thermal water or brackish

- Grouting in tanks containing very aggressive water, such as sewage treatment tanks

- Bonding thresholds and windowsills in marble

- Gluing tiles in fiberglass swimming pools

- Bonding special pieces of tiles.

Kerapoxy is made from epoxy resin, siliceous sand plus some special components that guarantee a good resistance to acids and excellent cleanability.

This product is very versatile and it can be use to execute grouting glass mosaics, even if they have joints less than 3 mm. After application, the product provides a final surface smooth, compact, non-absorbent; in fact, it is easily cleanable and resistant to cracking.

After application, the product provides a final surface smooth, compact, non-absorbent; in fact, it is easily cleanable and resistant to cracking.

The epoxy grout typically, having a rather pasty composition doesn't shrink and consequently is less subject to phenomena of cracking and formation of cracks.

79749 REGISTERED USERS