Brick in polymer

Post from EditorialsBuild a simple house with plastic bricks, now you can! Many research groups are investigating the matter; the latest results in Italy.

Brick: the project of the Italian polymeric brick

The bricks have been since ancient times the main elements of construction. In the course of time there have been further developments as regards shapes and materials; man has tried to respond to the needs of sustainability and respect for the environment, creating ever lighter materials, which respected the principles of green building, such as the bio bricks.

In Italy, more precisely in the city of Brescia, a 31 years old engineer Cristian Fracassi, has created a prototype of a polymer brick, made entirely in plastic. The project is called Brick, and is part of a series of innovative studies born in Valpadana, and is followed by a company called ISINNOVA. The idea that drove the young engineer to realize this type of plastic brick was born after the earthquake in Aquila, because of which were destroyed numerous buildings.

The idea that drove the young engineer to realize this type of plastic brick was born after the earthquake in Aquila, because of which were destroyed numerous buildings.

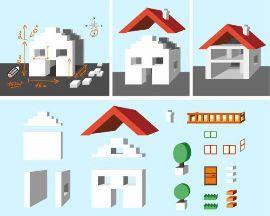

His goal became to find a new construction principle, which uses different materials and give the possibility to build a house as happens with Lego bricks, with a structure quick, safe, affordable and lightweight.

The project involves also the University of Bergamo and Confindustria.

These bricks, as designed by the engineer, would be assembled by following the instructions, just like Lego bricks. The revolutionary aspect is that the products made in this way can then be disassembled and reassembled again if the project realized does not please the customer. The houses built with polymer bricks would enjoy, according to studies of the engineer, also excellent insulation capacity and would be equipped with some sensors capable of evaluating the seismic risk in the houses.

The houses built with polymer bricks would enjoy, according to studies of the engineer, also excellent insulation capacity and would be equipped with some sensors capable of evaluating the seismic risk in the houses.

Obviously after the construction must be attested the habitability of individual homes.

To date, the design phase of the polymeric bricks now ended; then you have to move on to the industrialization that still needs funds for the construction of the plant for their creation.

Surely the idea is innovative and technologically advanced in the world of construction, and will definitely improve the way of living and build a house.

Recycled plastic to build bricks

The study of plastics to make building materials similar to concrete, from polymers from plastic waste was processed in Europe.

The goal is always to produce innovative bricks, less expensive than the traditional bricks and with a good fallout on the environment, as produced by the transformation of the polymers present in non-recyclable waste.

When you follow the recycling of plastic materials, about the 25% of the polymers in the total waste is unsuitable for recycling. This is because some products that contain plastic polymers are not suitable to the processes of regeneration, so for these materials is not possible to perform the recycling.

They then seek alternative solutions to avoid the waste and recover as much plastic as possible.

Some studies have been carried out by a group of researchers from the Latvian Technological Centre and from the Institute of mechanics of polymers of the University of Latvia in cooperation with Hormigones Uniland, Spanish cement industry.

This project is called SANDPLAST and has developed a technology for the production of materials that starting from non-recyclable waste plastics leads to the production of a material very similar to concrete and with its own properties, even higher. It is able to produce a binding substance that, mixed with inert elements such as sand, allows to realize polymeric bricks similar to concrete, light and with excellent insulating properties, but actually made with plastic materials.

It is able to produce a binding substance that, mixed with inert elements such as sand, allows to realize polymeric bricks similar to concrete, light and with excellent insulating properties, but actually made with plastic materials.

This material absorbs less water then concrete and is therefore more reliable in certain environmental conditions, such as cold weather.

In the world of modular plastic bricks, the company Easy Brick has created a modular system simple and imaginative allowing it to be used for many uses. The bricks of this company allow you to build, in complete safety.

The bricks of this company allow you to build, in complete safety.

You can make small walls separators and small buildings habitable.

The modular system proposed by the company is self-extinguishing, resistant to cold, aging caused by the sun, the wind, and has an excellent sound insulation due to its thickness of 12.5 cm. It can be mounted easily, without soil and without the use of tools or special tools.

The assembly can be done via the joint of the components, with the addition of bolts for fixing. The resulting structure is solid and secure, weatherproof and resistant to climate change. The plastic bricks EasyBrick have been tested thoroughly and certified for outdoor use. They resist water, snow and even moisture.

The plastic bricks EasyBrick have been tested thoroughly and certified for outdoor use. They resist water, snow and even moisture.

All components are removable and reusable, they allow you to create covers for balconies, terraces and gardens, dividing apartments and sheds, garages, furniture for indoor or outdoor, playground.

These innovative bricks will allow you to build practically, in a simple and intuitive way.

79733 REGISTERED USERS