Consolidation of the masonry infill wall

Post from EditorialsAs intervene on infill walls when they manifest signs of detachment from the bearing structures perimeter in order to improve stability.

The importance of the masonry veneer walls

The perimeter walls that surround the buildings with reinforced concrete structure, commonly known by the term masonry veneer or the infill wall have a particular importance for the safety and comfort of the building. To them is given the task of dividing the interior from the outside through the use of different materials coupled with other insulating special powers aimed at satisfying every need and design performance.

To them is given the task of dividing the interior from the outside through the use of different materials coupled with other insulating special powers aimed at satisfying every need and design performance.

The most common infill walls are made with thermoblocks brick or with two linings of the same material spaced apart by an air chamber, which can also accommodate thermally insulating materials, made from sheets of rigid or loose materials.

Following numerous earthquakes that have occurred throughout the country, it was found that these parts of the buildings are easily subject to phenomena of expulsion and crushing of brick blocks, with serious consequences for the safety of people.

The vulnerability of infill walls

For this reason, the national bodies in charge of drawing up standards for more secure buildings have provided the obligations to those who design and build these works, in order to better secure their stability at events capable of dynamically urge the supporting structures connected to them. Although the legislation has tried in some way to regulate a more stringent rules for the design and construction of such walls, today you can not even say that they are complete to define the problem in a comprehensive way.

Although the legislation has tried in some way to regulate a more stringent rules for the design and construction of such walls, today you can not even say that they are complete to define the problem in a comprehensive way.

Extreme events like earthquakes are not the only cause of destruction of these parts of the building, there are actually a number of causes more or less known that decreed the weakening and in severe cases the collapse.

Work carried out in haste, without regard to the time required to allow the bonding agents used to join properly the successive rows of blocks, bad or missing casing under the structural framework of infill, poor quality of the binders, excessive height of the wall, defects of clinching, represent some of these causes over time with the help of external agents, such as microsystems caused by vehicular traffic or other types of shaking induced on structures by machinery in motion trigger processes of dangerous instability.

The famous statement prevention is better than cure is apt occur when detachments of infill the perimeter structures, lesions with expulsions of some pieces of brick, strapiombature, etc.

Strengthening interventions in case of loosening of infill walls

In the presence of an overt loosening of the infill, when the percussion with a punch to the center of the wall highlights a certain instability of the same, it is necessary to intervene to restore the damaged link by a process which can vary in relation to the extension of the separation and of the localization of the same. In fact if the infill wall is only detached from the beam above for lack of embedding can take action only on that part, while if the infill proves low-cut away in a clear manner is necessary to operate in a more invasive way.

In fact if the infill wall is only detached from the beam above for lack of embedding can take action only on that part, while if the infill proves low-cut away in a clear manner is necessary to operate in a more invasive way.

Let's see how we proceed to carry out the restoration of damaged connections between structure and perimeter walls.

In the presence of a disconnect of an infill wall, with respect to the external frame is basically possible to act in two ways and precisely restoring the cohesion between the masonry and the structure using the introduction of foaming gripping materials, or by means of connecting bands perimeter anchored the two parts to join.

The first solution can be used in the presence of delaminations are not relevant and of curtains not very slender, for instance it is possible to proceed on the walls of headroom max up to m.3,00, using one-component polyurethane foam ready for use and extrudable through a special pistol of universal type. In the second case, when the stability of infill should prove very compromised, it is necessary to proceed in a more invasive way.

In the second case, when the stability of infill should prove very compromised, it is necessary to proceed in a more invasive way.

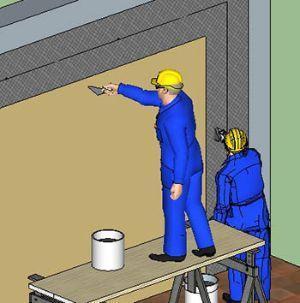

in fact the intervention of connection should be made by operating from the inside and from the outside in the same way and that is perimetrically by removing 25 cm of plaster from the masonry and the adjacent perimeter structure.

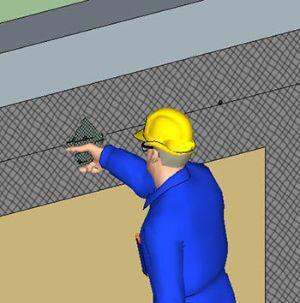

Later, after careful cleaning of the surfaces it is necessary to drill at constant distance of about 150 cm the adjacent wall with the structure, in order to be able to enter it later a network connecting the bands of glass fiber laid down on the surfaces described by means of cement mortar.

Described will be inserted in the holes of the connectors constituted by tissues of glass fiber loops, with implications of about 30 cm on the two faces of the infill.

It will proceed finally to the grouting of the holes previously treated with resins suitable to allow the anchoring of the connector, after grouting will be performed the layers of finish in relationship to the type of pre-existing finish.

In place of the connectors consist of fiber glass, it is possible to employ steel rods equipped with threaded washer fiberglass very similar to the anchors used to attach the insulation coatings. It is immediately apparent that the two procedures but different as invasiveness and use of materials in any case reduce the risk of tipping of the wall, which would also intervening on the side connection panel ensures complete stability.

It is immediately apparent that the two procedures but different as invasiveness and use of materials in any case reduce the risk of tipping of the wall, which would also intervening on the side connection panel ensures complete stability.

The costs of the two measures are very different, by virtue of the fact that in the first case, the operation can also be carried out without the use of workers particular by those who have a good manual employing polyurethane products adequate and following the operational requirements listed in the datasheet of the product.

In the second case it is necessary the intervention of adequate company followed by a qualified professional, who has the task of directing the work and to calculate any further checks on the consistency of the infill to be consolidated.

In fact a disconnect very obvious and widespread of the works infill perimeter may not be attributable solely to the reasons set forth above, but may be the result of structural failures.

79857 REGISTERED USERS